Our Projects

Experience you can trust.

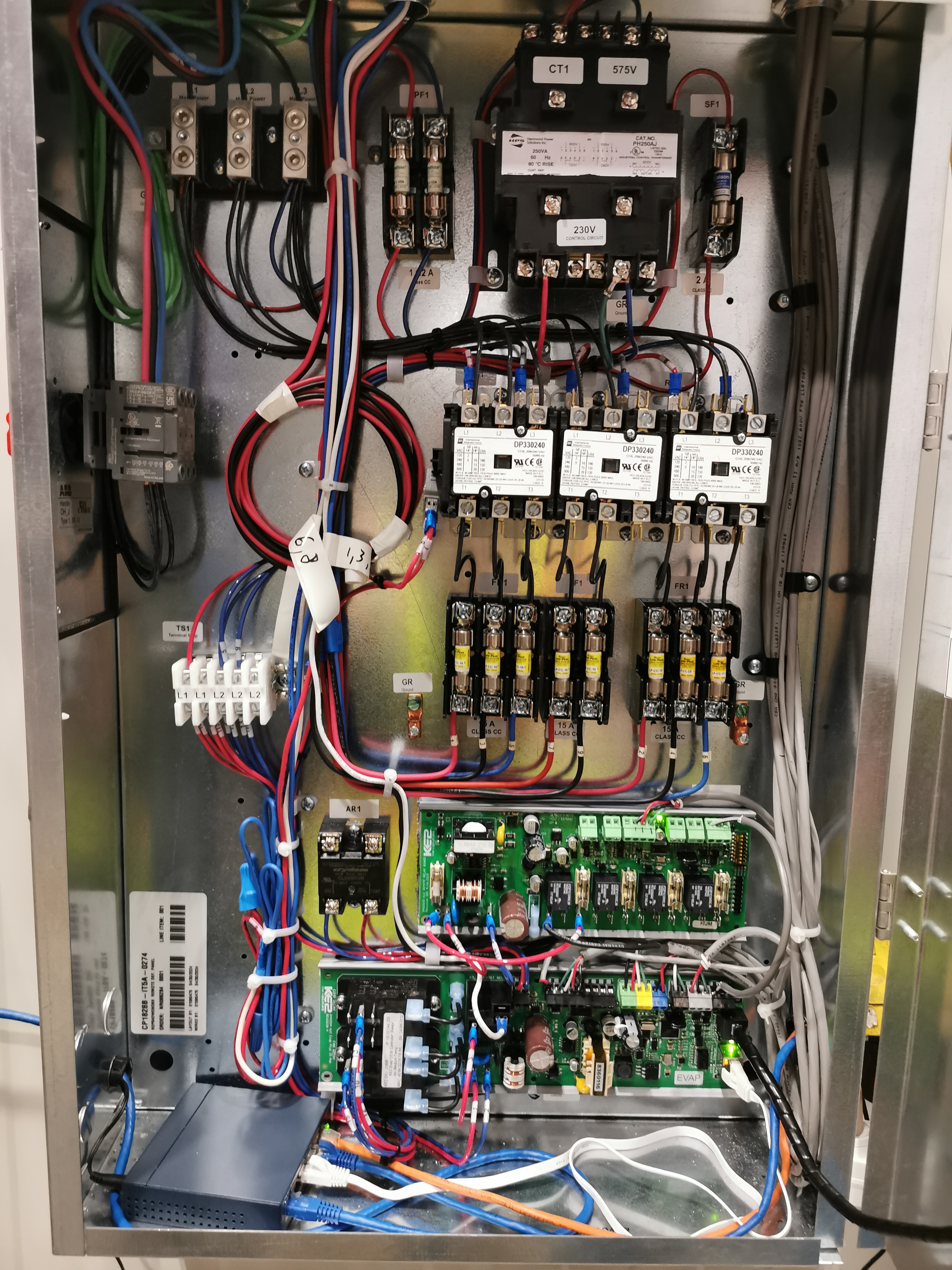

High-Care Pharmaceutical Distribution Warehouse

A 600 sqft box-in-box storage cooler and a 150 sqft blast freezer.

A small but complex project that features a cooler, temperature and humidity controlled to within +/- 1 degree of the setpoint temperature. Complete with redundant lead-lag refrigeration systems, demand defrost, and an integrated control system communicating with the client's existing controls for real-time remote monitoring and alarms using their existing building management system.

Careful consideration was given to the temperature deviations as a result of the large traffic door and reach-in doors while maintaining a tight temperature differential.

Cold Chain Distribution Centre

93,000 sqft in total of purpose-built refrigerated areas, including a storage freezer, storage cooler, and shipping/receiving cold docks.

Featuring only roof-mounted CO2 refrigeration equipment, this project highlights the quick and cost-effective installation of modular industrial refrigeration equipment. The refrigeration system was built off-site by the manufacturer. The work on-site was limited to lifting the equipment into place, interconnecting pipework, ductwork, and electrical connections.

A design-only project, the completed refrigeration plans and equipment specification were handed off to an installer for a timely project execution.

Refrigerated Cross Dock

A 15,000 sqft cold chain logistics hub.

An existing dry dock converted to a cold dock. As a prefabricated building, the roof was not able to support the refrigeration equipment. Utilizing cost-effective synthetic-split refrigeration equipment, the condensing units were pad-mounted at the side of the building.

Food Production Facility

Featuring 36,000 sqft of refrigerated space, this CFIA facility produces ready-made meals from start to finish.

A unique aspect of this project is the absence of typical ceiling-hung unit coolers in the refrigerated production space. Only short lengths of ductwork are present inside the facility's 13 temperature-controlled rooms, resulting in a minimally-intrusive solution that reduces noise and improves employee comfort.

This project features self-contained, roof-mounted equipment utilizing free cooling. When the outside temperature permits, outside air is used for cooling, resulting in energy savings of 90% compared to mechanical cooling.